Learn The Pros And Cons Of Using Ball Screws

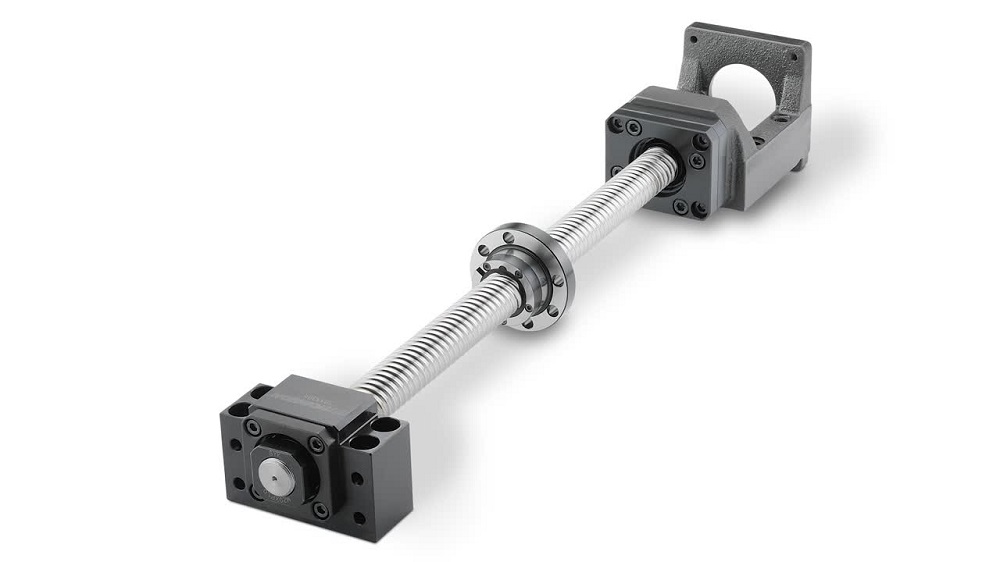

Among all the screws in the electronic or machinery industry for motion, ball screws offer unique advantages when compared to other standards. Ball screw is popularly known as an antifriction nut to convert rotational into linear motion.

Ball screws have long threaded shafts with ball bearings that endure stress and weight to minimise friction. The ball screw rotates, and the ball bearings travel to treat the system ahead of the change of direction.

Here are the pros and cons of using ball screws.

· Ball Screws Vs Lead Screws

The ball screw and lead screw look the same, but the ball screw has a ball bearing inside the nut. Whereas in the lead screw, the nut doesn’t have any ball bearings, nor does it easily roll. In contrast, ball screws have a nut in which ball bearings rotate to support the load and decrease friction.

· Pros Of Using Ball Screw

Accordingly to statistics, a Ball screw provides a high level of mechanical efficiency.

· High Efficiency

Ball screw typically performs at a minimum of 90 per cent capacity. Ball screws are three to four times more mechanically efficient than other screws. This is the reason that makes them an optimal choice in inducing rotary motion into precision linear motion.

· Load Capacity

Ball screw is the no one choice of machinery industry because it can carry remarkably heavy loads quickly and efficiently. The screw life is much more durable than any other type of screw.

· Coast Efficient

In the long run, the concept of a ball screw can be established as a cost-effective alternative to pneumatic or hydraulic systems that need continuous electrical and air power.

· Cons Of Using A Ball Screw

The only con of using ball screws is their responsiveness to being back-driven. Because they make less friction, they can be back-driven at top angles. Other than the disadvantages of back-driven, ball screws are pricier than comparable mechanical devices. For small manufacturing companies with a low budget, it would be difficult to use high-cost ball screws in their company. Due to its superior mechanical efficiency and low internal friction, ball screw is the favourite in manufacturing companies who want to uplift the quality and performance of their products.

Conclusion

The ball screw is a high-efficiency feed screw with the ball inside the nuts. Compared to other conventional sliding screws, it is the best suitable for protecting drive motor power. Visit https://inb.co.th/th/products/bnt-th/ to know the best price for a ball screw.